Climate Change Measures

NSK’s Approach

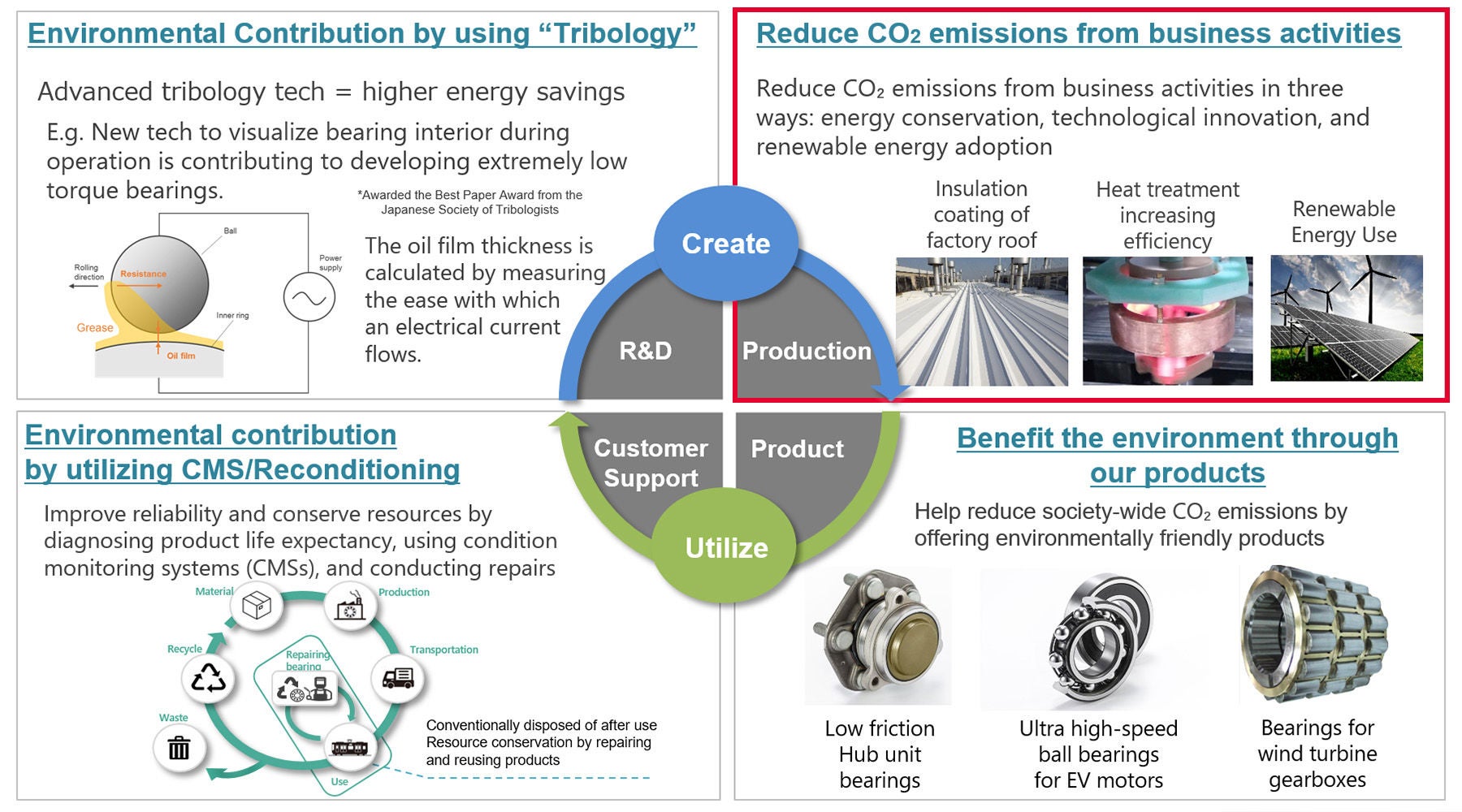

◆Promoting CO₂ Emissions Reductions through “Create” and “Utilize” Approach

In response to the urgent issue of climate change, NSK contributes to achieving carbon neutrality across the entire supply chain. NSK works to reduce energy consumption and CO2 emissions not only during the “create” stage, when products are manufactured, but also throughout the entire product life cycle, including the “utilize” stage by customers. Furthermore, the products NSK provides contribute to the efficient use of resources by incorporating the concept of a circular economy. By leveraging its core technologies, honed over more than 100 years since our founding, NSK is dedicated to contributing to the realization of a sustainable society.

- This page outlines NSK’s activities for reducing CO2 emissions during the “create” stage, from the procurement of raw materials and components to the manufacturing and shipping of products. For information on how our products and services reduce CO2 emissions during the “utilize” stage, please visit “Environmentally Friendly Products.”

Environmentally Friendly Products

Information Disclosure Based on TCFD Recommendations

Targets and Performance

◆Mid-Term Management Plan 2026 (MTP2026) Targets, with Targets and Performance for Each Fiscal Year

| MTP2026 targets | FY2023 targets | FY2023 performance | Initiatives | FY2024 targets | ||

|---|---|---|---|---|---|---|

| Fighting global warming and climate change | Manufacturing, technology, offices | CO₂ emissions*: 50% reduction from FY2017 | 45.0% reduction from FY2017 | 51.7% reduction from FY2017 | (1) Promotion of energy savings and fuel conversion

(2) Production technology innovation

(3) Expanded adoption of renewable energy

◆ Mechanisms to promote measures

| 39.0% reduction from FY2017 |

| Energy usage per unit of sales: 10% reduction from FY2017 | 6.0% reduction from FY2017 | 19.4% reduction from FY2017 | 7.7% reduction from FY2017 | |||

| Distribution (Japan) | CO₂ emissions by transport volume: Continue to reduce by 1% year on year | Below 4% (base year FY2017) (1% reduction from FY2021) | 0.5% (base year FY2017) (Reduced by 4.3% from FY2021) |

| Below -0.5% (base year FY2017) (1% reduction from FY2022) | |

* Total greenhouse gas emissions (CO2 equivalent) are obtained by multiplying each type of gas by its global warming coefficient. Emission factors for electricity are variable market standards. These emission factors, which change every year, are published by power companies with which we have contracts, or are given in the International Energy Agency’s CO2 Emissions from Fuel Combustion.

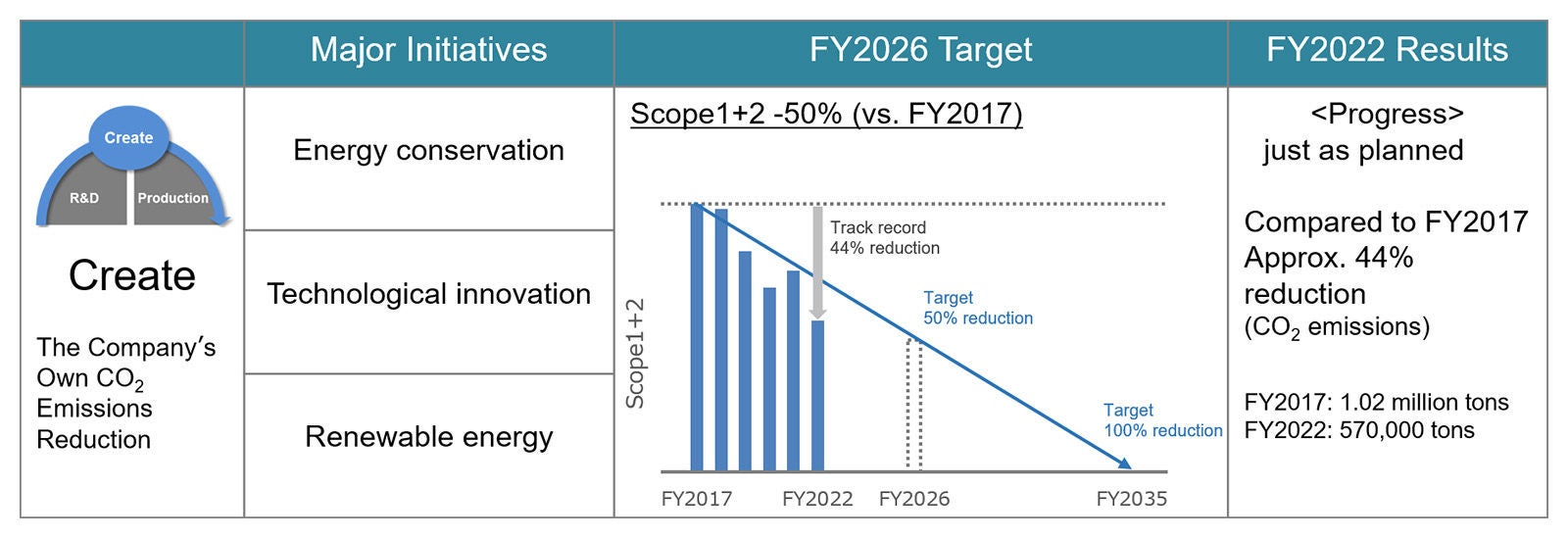

CO₂ Reduction Targets and Progress

- Aim to reduce Scope 1 and 2 CO2 emissions by 50% by FY2026 from FY2017 levels.

- Aim to achieve carbon neutrality for Scope 1 and 2 by FY2035.

- Aim to reduce Scope 3 CO2 emissions, including those generated in the upstream supply chain, and to help the global community achieve net-zero CO2 emissions by 2050.

Initiatives

Initiatives on “Create” Approach

(1) Energy Conservation

NSK plants are pursuing more advanced energy management by utilizing digital tools to monitor and analyze the energy consumption of each piece of equipment. Building on this foundation, the plants are deploying energy-saving initiatives such as improving the operational efficiency of production equipment, reducing compressed air consumption, optimizing the number of compressors in operation, and enhancing the energy efficiency of air conditioning systems.

- Coating Plant Roofs with Thermal Insulation Paint

Coating plant roofs with thermal insulation paint not only reduces radiant heat caused by sunlight in summer but also prevents heat loss in winter. Since it has proved effective after application at NSK Saitama Plant, we are in the process of rolling it out to the Fukushima Plant and other plants. We also plan to apply this coating to the exterior walls of heat treatment furnaces to improve the work environment and reduce the risk of burns.

Thermal insulation paint on the roof of the Saitama Plant

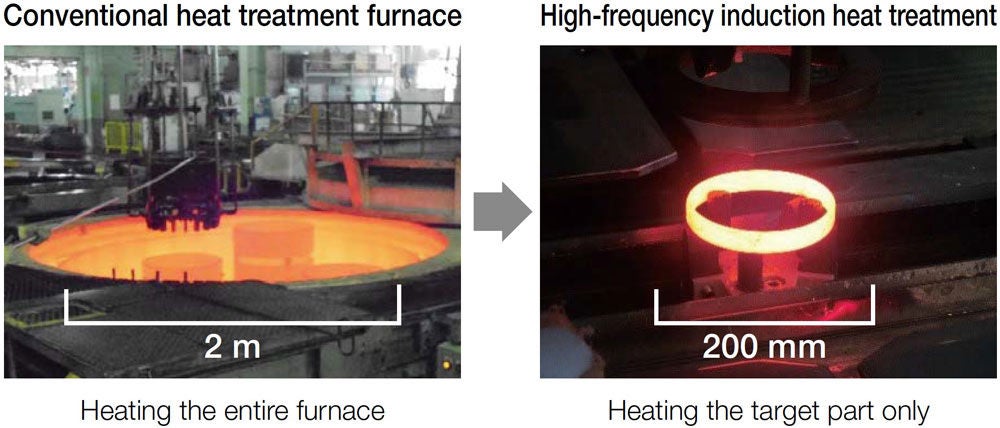

(2)Technological Innovation

- High-Frequency Induction Heat Treatment

To address the challenge of reducing CO2 emissions in the heat treatment process, we have developed high-frequency induction heat treatment technology and are actively deploying it at NSK plants worldwide. Unlike conventional heat treatment methods, which heat parts by surrounding them in a gas-heated furnace, high-frequency induction heating rapidly and efficiently heats only the part itself. At the Ishibe Plant, the introduction of high-frequency induction heat treatment has not only reduced CO2 emissions but also optimized equipment space utilization, contributing to a safer and more beneficial workplace

We will also work to reduce CO2 emissions by improving productivity through the use of digital technology and other means to super-stabilize production.

(3) Renewable Energy

In Europe, a leading region in renewable energy, we have switched to 100% CO2-free electricity at all production sites. We are also accelerating its adoption in Japan. Additionally, we are gradually expanding the installation of solar power generation equipment at our production sites and offices worldwide.

Partager